Traditional yoghurt

In the technology of making yoghurt, bacteria remain alive in the yoghurt and lay on its surface, resulting in the characteristic skin that traditional yoghurt has and they are none other than the beneficial bacteria belonging to the species Lactobacillus Bulgaricus and Streptococus Themophilus.

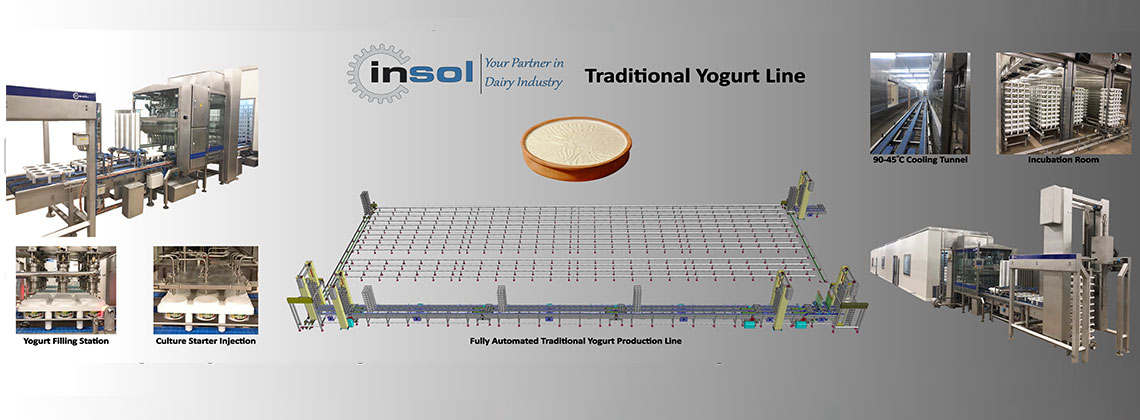

An innovation at traditional yoghurt production that replaces the old fashion manual procedure.Insol is the one and only company in the world that has develop and manufactures that automative yoghurt production line. Ensures the stability and quality of the production, minimizes the manpower and standardizes the production process.

- Tray de-stacker

- Step by step conveyor

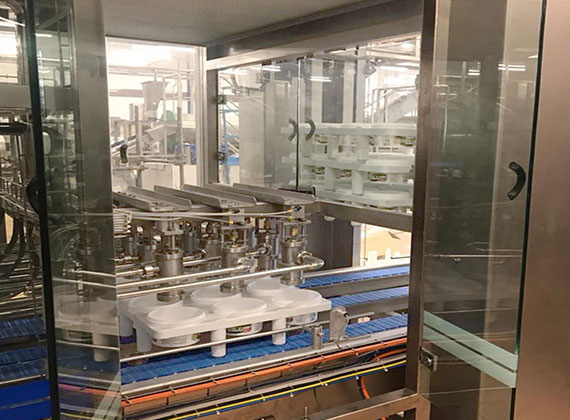

- Cup filling station

- Milk filling machine 90οC

The filler consists of 12 filling heads, adjusted to flow measurement method with PLC, non-return valve and nozzle for cleaning station with CIP system. Accurate filling and dosing of product.

- Cooling tunnel with a smooth-moving conveyor

- High efficiency

- Energy efficient system design

- Uniform cooling of the products

- Optimal adaptation to operating conditions

- Smart designed hygiene and service concept

The station is made of stainless steel AISI 316. The culture starter is filled by 12 dosing heads. The filling mechanism includes adjustable dosages of 4gr - 20gr with 12 injection system valves and an AISI 316 stainless steel culture starter balance tank. Cleaning of the station by CIP system.

The filling mechanism includes adjustable dosages of 4gr - 20gr with 12 injection system valves and an AISI 316 stainless steel culture starter balance tank. Cleaning of the station by CIP system.

Final stacking of the trays with yoghurt and transfer to the incubation rooms.

Exit cooling room and packing.

The packaging machine has the ability to seal plastic cups by aluminum foil or film and cup. Manufactured according to CE standards of the European community.

English (United Kingdom)

English (United Kingdom)  Ελληνικά

Ελληνικά